Strep-Tactin® 4Flow® high capacity - New agarose resin

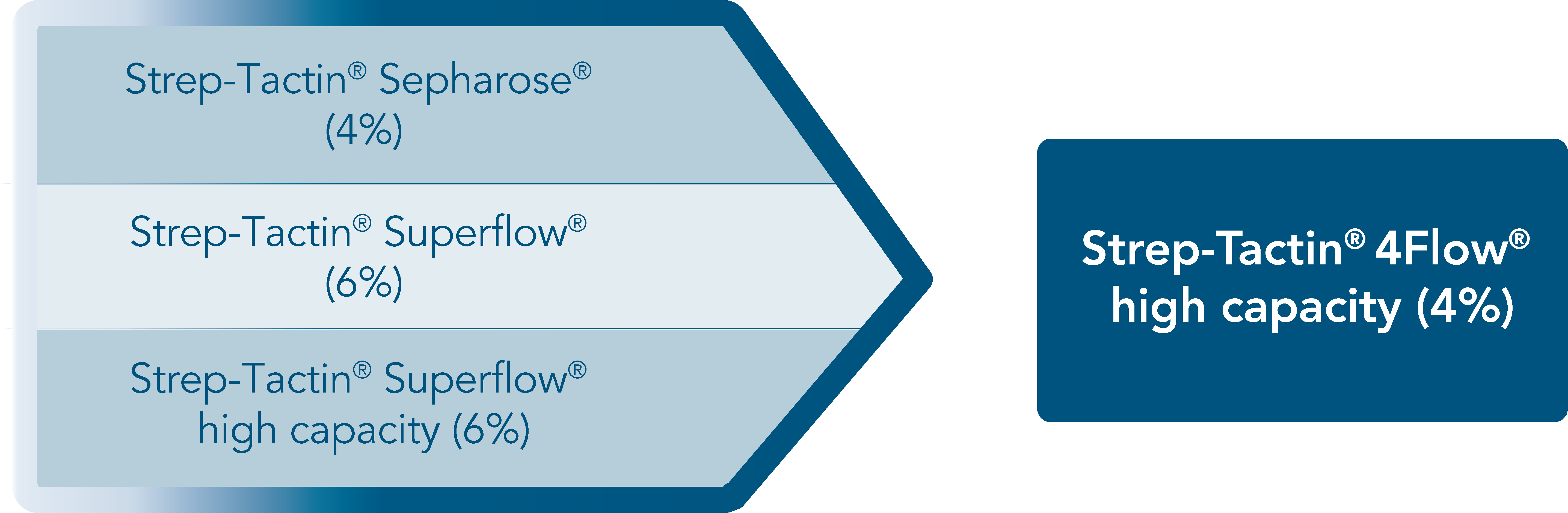

Strep-Tactin® 4Flow® high capacity replaces:

- Strep-Tactin® Sepharose® (2-1201-002, 2-1201-010, 2-1201-025, 2-1201-500, 2-1202-550, 2-1202-001)

- Strep-Tactin® Superflow® (2-1206-025)

- Strep-Tactin® Superflow® high capacity (2-1208-002, 2-1208-010, 2-1208-025, 2-1208-500, 2-1209-001, 2-1209-051, 2-1209-101, 2-1209-550, 2-1239-001, 2-1240-001)

providing identical performance and unifying the resins.

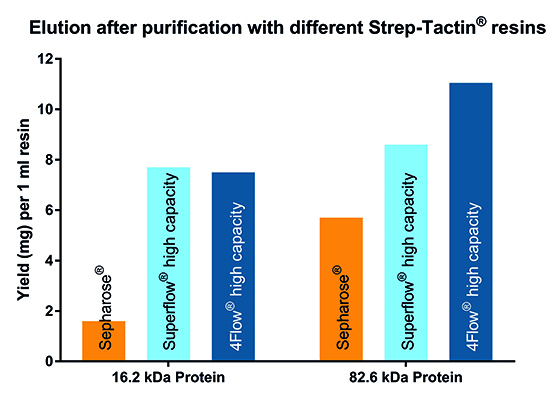

Strep-Tactin® 4Flow® high capacity consists of a low concentrated (4%) and pressure stable agarose coupled with high Strep-Tactin® density. These specifications lead to

- high protein binding capacity

- applicability for FPLC work stations

- high yields for all protein classes and especially large proteins

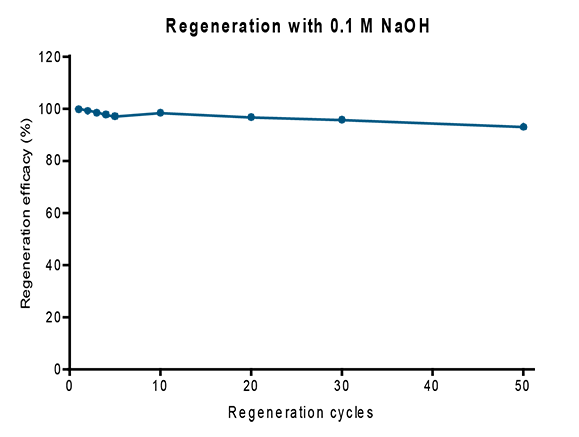

with the usual high target purities. In addition, this new resin is characterized by a superior stability enabling at least 50 regeneration cycles.

Do you know the high affinity version of Strep-Tactin® 4Flow® high capacity?

What is the difference between Sepharose®, Superflow® and 4Flow®?

The underlying matrix of many protein purification resins are porous agarose beads. The characteristics of these agarose beads determine for which proteins and for which applications the resin is most suitable. IBA’s Sepharose® resin consists of a 4% cross-linked agarose and is therefore suitable not only for small, but also for large proteins. However, a disadvantage of Sepharose® is that it is not pressure stable and consequently not suitable for automated applications such as FPLC. In contrast, IBA’s Superflow® products work well for FPLC. The disadvantage of Superflow® is that it consists of a 6% cross-linked agarose. This means that the pores are smaller and not accessible for larger proteins, resulting into low yields.

4Flow® combines the advantageous characteristics of Sepharose® and Superflow®. It is a 4% cross-linked agarose, and it is pressure stable, making it a universal matrix for small and large proteins as well as for different applications such as FPLC.

| Matrix | Strep-Tactin® Superflow® | Strep-Tactin® Sepharose® | Strep-Tactin® 4Flow® |

|

Bead structure |

6% agarose, crosslinked | 4% agarose, crosslinked |

4% agarose, highly crosslinked |

|

Bead size |

60-160 μm, spherical | 45-165 μm |

50-150 μm, spherical |

|

Exclusion limit |

6 x 106 Da | ~3 x 107 Da |

3 x 107 Da |

|

Recommended flow

rate | 1 ml FPLC column: 0,5-1 ml/min 5 ml FPLC column: 1-3 ml/min | gravity flow |

1 ml FPLC column: 0,5-1 ml/min 5 ml FPLC column: 1-3 ml/min |

| pH range for protein binding | 7-8 | 7-8 | 7-8 |

| Max pressure | 9.6 bar | gravity flow | 3.5 bar |

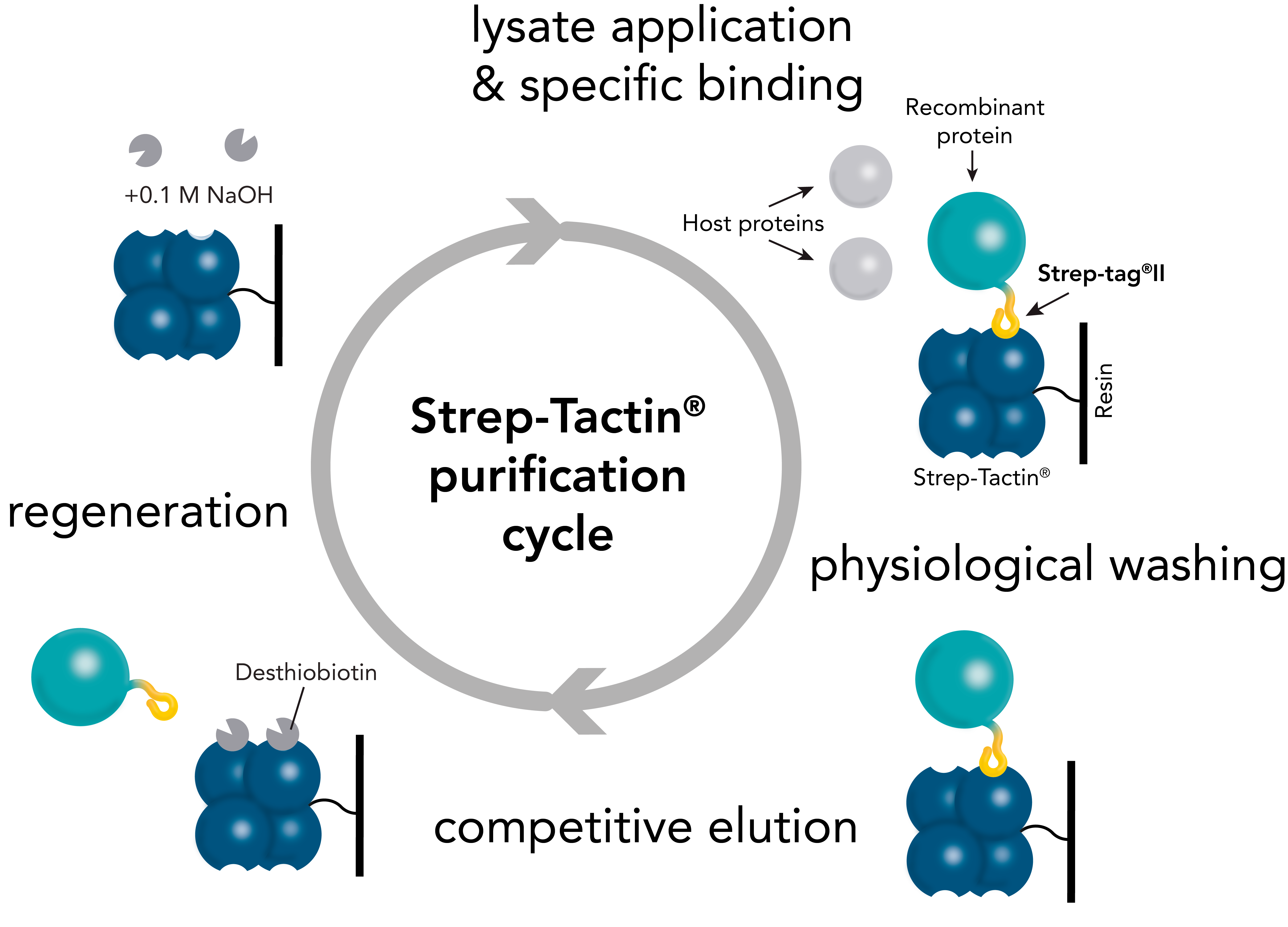

| Eluent | desthiobiotin | desthiobiotin | desthiobiotin |

| Regeneration buffer | Buffer R | Buffer R | 100 mM NaOH |